Model No.︰SAFS-FM001

Brand Name︰SAFS

Country of Origin︰China

Unit Price︰US $ 200 / S/M

Minimum Order︰200 S/M

Structure Type

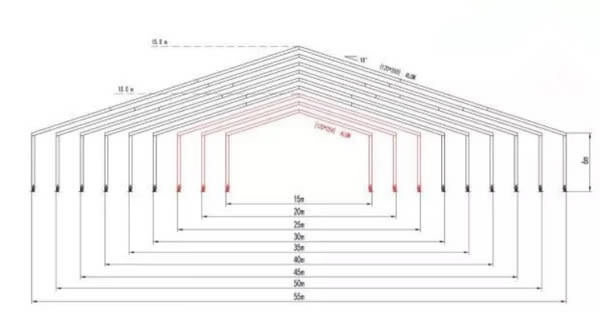

The plane layout and height requirements of the hangar are special, which directly affects the structure of the hangar.

Due to the large span of the hangar, the structural weight (mainly the roof system) accounts for a large proportion of the total load.

If the structural weight can be reduced, obvious economic benefits can be achieved.

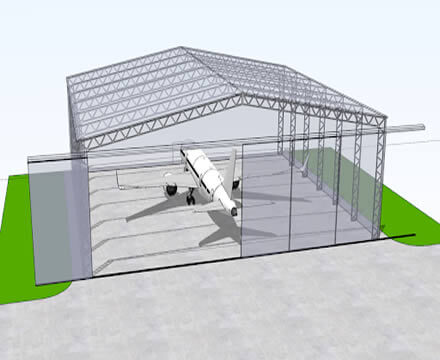

The steel structure hangar has the advantages of high strength, lightweight, small section, good weldability, and simple manufacturing process.

Quick Details

The hangar uses the advantages of tents for flexible and rapid deployment, low cost of ownership, repeated disassembly and assembly, wide application range, diverse and flexible shapes, a rich selection of materials and accessories, and personalized customization, providing a cost-effective solution for aviation hangars; Design and customize professional-level hangar tents and overall equipment plans for different models.

| Standard: | AISI, ASTM, bs, DIN, GB, JIS | Grade: | Q235/Q345 Carbon Steel |

| Place of Origin: | Jiangsu, China | Brand Name: | SAFS |

| Model Number: | Steel Structures | Type: | Light, Light Steel Structure Frame |

| Application: | Hangar/Warehouse/workshop/sheds/poultry house /office building | Tolerance: | ±3% |

| Processing Service: | Bending, Welding, Decoiling, Cutting, Punching | Product name: | steel structure hangar |

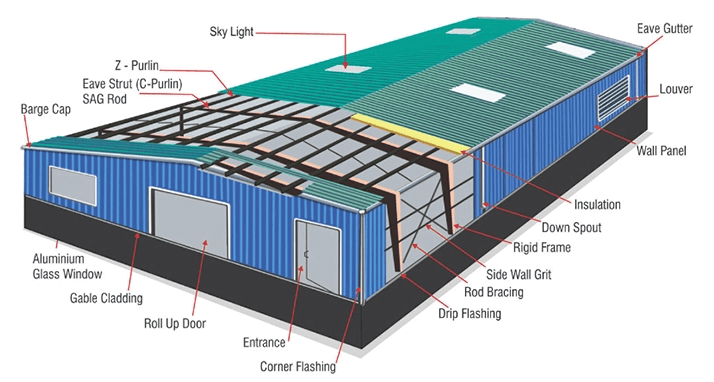

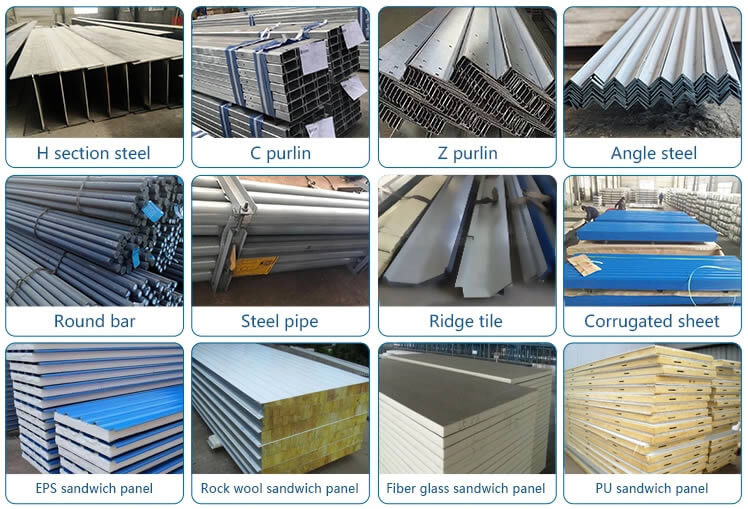

| Main structure: | Section Column | Purlin: | C/Z Galvanized Steel(Q235) |

| Surface treatment: | Painting or Galvanizing | Wall&Roof panel: | Steel Sheet or Sandwich Panel |

| Structure type: | Light Portal Frame Structure | Certificate: | ISO9001:2008 ISO14001:2004 |

| Life span: | Up to 50 Years | Wind Resistance: | 180km/h |

1. The whole hangar adopts a steel structure frame. The surroundings can be equipped with hard ABS board walls and sandwich board walls. The entrances and exits can be equipped with blue flexible retractable doors and sliding doors. The overall appearance is beautiful and the safety performance is high. The wind resistance can reach 120 km/h (wind load 0.7 kN/m²), and the structure is sturdy and durable.

2. The support is made of high-strength aluminum alloy 6061/T6, hardness HW≥14, aging oxidation, tensile strength: 290Mpa, yield strength: 270Mpa, elongation: 13%;

3. The roof tarpaulin material adopts shading double-sided PVC synthetic fiber cloth, which is pre-stretched, tarpaulin and aluminum alloy bracket;

The surface is tight after the connection, completely isolated from ultraviolet rays, waterproof, the thickness of the fabric is 0.76mm, and the weight is 1100g/㎡;

Tensile strength (warp/weft): 3553/2939N/5cm, tear strength (warp/weft): 462/348N,

peel strength Degree (longitude/latitude): 118/116N/5cm, applicable temperature: -30℃ to +70℃.

Supply Ability

Supply Ability: 100000 Square Meter/Square Meters per Month steel structure workshop

Packaging & Delivery

Packaging Details

steel structure hangar

1) Steel structure components will be in nude packaging with proper protection.

2) Sandwich panels will be packed with plastic film.

3) Doors and windows will be packed with bubble plastic.

4) Bolts and another accessory will be packed in wood boxes.

Normally is 40’HQ and 40’OT container.

If you have specifical requirements,40GP and 20GP container are ok.

Port

QINGDAO PORT/LIANYUNGANG PORT/SHANGHAI PORT

Lead Time :

| Quantity(Square Meters) | 1 – 2000 | 2001 – 5000 | 5001 – 10000 | >10000 |

| Est. Time(days) | 25 | 35 | 45 | To be negotiated |

Drawings & Quotation

1) Customized design is welcomed.

2) We have an excellent design team. According to the requirements of different projects and clients, we will supply different designs and steel products. In order to give you an exact quotation and drawings, please let us know the following information. We will quote for you promptly.

Basic design requirements of steel structure hangar

| Basic Design Requirements | ||

| 1.Project location | 5.Length (sidewall,m) | 9.Window quantity, size |

| 2.Snow load | 6.Width (end wall, m) | 10.Door quantity, size |

| 3.Wind load | 7.Wall Height (eave, m) |

11.Brickwall needed or not. If yes, 1.2m high or 1.5m high |

| 4.Seismic magnitude | 8.Middle column allowed or not |

12.Crane needed or not |

|

13.Thermal insulation. If yes, EPS, fiberglass wool, Rockwool, PU sandwich panels will be suggested; If not, the metal steel sheets will be ok. The cost of the latter will be much lower than that of the former. |

||

Engineering Design Software:

AutoCAD,PKPM,MTS,3D3S, Tekla Structures(X steel)V12.0.etc

| Items | Specifications | |

| Main Steel Frame | Column | Q235,Q345 Welded H Section Steel |

| Beam | Q235, Q345 Welded H Section Steel | |

| Secondary Frame | Purlin | Q235 C and Z Purlin |

| Knee Brace | Q235 Angle Steel | |

| Tie Rod | Q235 Circular Steel Pipe | |

| Brace | Q235 Round Bar | |

| Vertical & Horizontal support | Q235 Angle Steel, Round Bar, or Steel Pipe | |

| Maintenance System | Roof Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

| Wall Panel |

EPS, Glass Fiber, Rock Wool, Pu Sandwich Panel Corrugated Steel Sheet |

|

| Accessories | Window | Aluminum Window, Plastic Steel Window |

| Door | Aluminum Door, Rolling Metal Door | |

| Rainspout | PVC | |

| Fastener | High Strength Bolts, Normal Bolts, Chemical Bolts | |

| Ventilation System | Natural Ventilator, Ventilation Shutters | |

| Live Load on Roof | In 120kg Sqm (Color steel panel surrounded) | |

| Wind Resistance Grade | 12 Grades | |

| Earthquake-Resistance | 8 Grades | |

| Structure Usage | Up to 50 years | |

| Temperature | Suitable temperature -50°C~+50°C | |

| Certification | CE, SGS,ISO9001:2008,ISO14001:2004 | |

| Finishing Options | A vast array of colors and textures available | |

Main Characters

All the components will be prefabricated in the factory before transported to the construction site. The installation process is quick and easy.

It will significantly shorten the construction period of your buildings, saving a great deal of time and money.

The steel structure has a lightweight but high strength, which is also easy to maintain. It can be utilized for over 50 years.

The prefab steel workshop can be isolated against outdoor environments as well as avoid any leak like water seepage. It also has excellent fire resistance and corrosion resistance.

It is easy to move and relocate steel structure, which can also be recycled without pollution.

The steel structure fabrication workshop is capable of withstanding the attack of strong winds and heavy snow. It also has the excellent seismic performance.

The steel columns and steel beams of the internal frame are made of H-shaped steel through-bolt connection. This kind of building has lightweight, high strength, and large span. The exterior wall panels are made of lapped colored steel veneers, with a service life of 50-100 years. The attachment is made of colored steel, which has a good sealing effect. The wall and roof of the hangar are maintained by glass wool sandwich panels. The hangar has strong fire resistance and avoids the fire. The mainframe of the hangar is connected by bolts, which are simple to install. We can provide for installation. Technical Support. Regarding the transportation of the steel components of the hangar, we use the whole packing box to avoid the damage of the steel components during transportation.

Accessories

Shipping

Payment Terms︰ L/C, D/A, D/P, T/T, Western Union, MoneyGram

Packing︰ Special export packing. Strong enough for sea transportation.

Lead Time︰ 45days